Quality design-build services that meet the high demands of your industry

Secure, reliable execution every time.

When your facility design and construction affect the success of complex operations, you need a partner who delivers and delivers well. Our team offers consistent execution and agile solutions to keep your project on track.

$18.8M

in Aerospace + Defense experience3.2M

Aerospace + Defense square feet80+

Aerospace + Defense projectsYou'll be in good company.

Partner with the experts.

We're ready for every facility challenge and partner with you to provide:

Proven engineering and construction management on one team

Deep knowledge of the aerospace and defense industry

Ability to process and execute complicated solutions

Top-rated safety program and zero-accident culture

Ongoing communication and collaboration for rapid decision-making

SCIF design and construction expertise

Expert solutions for aerospace and defense clients in North America.

Aerospace & Defense

Designed a closed area with deck high walls with HVAC, lighting, security system and roll-up doors using Lockheed Martins standard finishes.

We help you stay on top of the latest aerospace and defense issues.

A Sensitive Compartmented Information Facility (SCIF) is constructed with the purpose of handling, storing, discussing, or processing confidential, secret and top-secret information. The goal is to provide physical security against a forced or covert entry into a space containing sensitive information along with technical security to prevent video or acoustic surveillance. The security requirements to protect against these actions need to be identified early to achieve an accredited SCIF that avoids costly delays and budget overruns. Beginning with the End in Mind The complex nature of SCIF design and construction places added importance and emphasis on the pre-construction phase. The below stakeholders must be involved early to assess and define the risk mitigation plan. Evaluating threats and vulnerability will get everyone on the same page regarding successful outcomes. A first step is identifying the intended use and classification of the space, such as a closed area or a radio frequency (RF) shielded facility. Also, the pre-construction documentation put together by the Site Security Manager (SSM) needs to be submitted to the Accrediting Official (AO) before the project moves forward into design. The project will have to be approved by the AO several times during the course of design and construction. Taking the time to meet with the stakeholders to gain an understanding of the desired classification, security measures, and depth of security wanted will be key in processing a complete project with no surprises that will risk the accreditation process. STAKEHOLDERS: Accrediting Official (AO): Person designated by the Cognizant Security Authority (CSA) who is responsible for all aspects of SCIF management and operations. Site Security Manage (SSM): Person designated by the AO who is responsible for all aspects of SCIF management and operations. Certified TEMPEST Technical Authority (CTTA): US Government appointed employee who has met and achieved requirements regarding TEMPEST. Mission Users: Person who will work, operate, handle SCI in the facility once the facility becomes operational. Architect/Engineer: The design of the SCIF shall be performed by US companies utilizing US Citizens or US Persons. General Contractor: The construction of the SCIF shall be performed by US companies utilizing US Citizens or US Persons. Security Measures Security is the main premise in designing and constructing a SCIF. Understanding and successfully designing and constructing the security requirements are the keys handing a successfully completed project to the owner. Security comes in layers when constructing a SCIF and can include items such as a security fence, an access control point entrance at the gate, an access control system in the building or an intrusion detection system. The physical perimeter of the SCIF space should include walls, floors, and ceilings with a sound transmission class (STC) rating of 45 or 50, radio frequency shielding, SCIF-rated doors and vault type construction. The penetrations for mechanical, electrical, fire protection and communication utilities should be limited and will require special design details. Lastly, it must be determined if adjacent areas require enhanced security to receive and maintain SCIF accreditation. Why It Matters This part is straight forward, a secured room is critical for protecting classified and sensitive information pertaining to US affairs and ongoing government projects. Therefore, you not only need this construction in the heart of government operations but at any facility that is engaged with government contracts pertaining to research and development, technology and information storage and general discussion of US affairs.

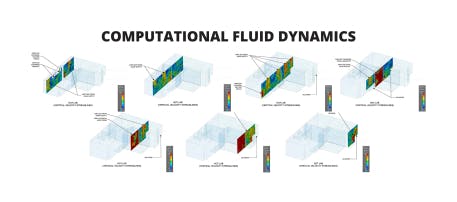

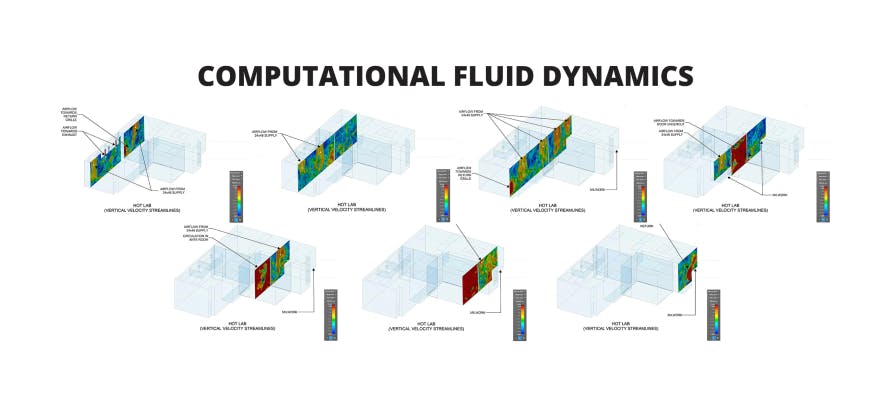

Computational Fluid Dynamics Modeling (CFD) is the art of modeling the air within a space as a fluid and analyzing how different variables such as air flow patterns, velocities, temperatures, and pressures can be affected by a room’s design and internal components. Utilizing both mathematical formulas and principles of physics the design team can model and view a representation of the phenomena related to a rooms’ function. CFD modeling is a critical pre-construction step used by engineers to compare the results of various facility options during the design phase. The CFD model allows engineers to optimize the space and pinpoint potential problems early which results in time and money savings in the design phase as well as reduced construction costs. How it Works Pre-Processing This is the beginning stage where the designers build out the geometry of the space and any associated equipment or obstructions within. Once the basic geometry of the room is modeled the team will start assigning boundary conditions such as flow velocity from a supply grille, supply air temperature, mass flow rates of the return grille(s). As the project progresses and an equipment plan is formed, designers export the equipment out of the building information model and into the CFD model. A heat flow rate associated to the equipment’s equivalent heat load distribution to the space is assigned to the equipment in the model and simulated. Solving Once the information has been set up within the program and the boundaries and internal conditions are set the software can begin to model the conditions assigned in the Pre-Processing stage. The initial conditions will be set and when the simulation starts the team is able to view a visual representation of the air’s fluid dynamical properties. By analyzing values such as velocity, pressure, temperature, and airflow, the team can identify, address and solve design problems that in normal design conditions may be overlooked. Post-Processing Once the results have been returned as values the team can then plot them as scaled color plots, contour plots and various other appropriate representations that can be used to enhance the overall design understanding of the space and advert any negative resolutions that were discovered during the testing process. These can also be shared with the client to detail why certain design changes were needed in a space, especially if the design change may seem odd or nonstandard at the time. Limitations of CFD Modeling Like all models, a CFD model is only as good as the inputs and assumptions used to create the model. It is imperative to hire a qualified, experienced engineer with the knowledge to gather a complete set of data and verify with field measurements where possible. Partnering with a diligent and thorough engineer will ensure the integrity and validity of your model for effective decision making. How Using CFD Modeling Upgrades the Design Process The modeling allows the designers to visually simulate the airflow patterns, temperature and pressure within a space. This enables the team to identify any low-pressure areas, hot spots and areas where the air tends to circulate but not escape and return. Prior to the advent of CFD modeling, engineers and designers often had to make the best assumption that they could with the information present, and using best practices assume the way the air would flow through the space. Now with CFD modeling, the design team can see exactly where the air will go and how to make the design the most efficient without costing the client change orders after the construction has started. For a C1S client, the engineering team was designing a cleanroom. While there are no standards for locating supply and return grilles, it was deemed appropriate to place the grilles on one wall assuming that the air would disperse across the room and circle back to the return grille. After the CFD model was complete, it was discovered that the velocity was high enough to disperse the air across the room, however the model indicated an entrapment of air in the corner of the room caused by the high velocity air which resulted in a lack of return air leaving. Being able to identify this before the room was being constructed saved the client unnecessary cost increases and delays. The design team was able to simply move the vent to the other side of the room to properly circulate the air.

Learn about the C1S Group Cleanroom design and construction process.

Find the right solution for your aerospace and defense project.

You can also give us a call at:

972.829.0148